GI Energy, the UK leader in the design and installation of Ground Source Energy Systems, is celebrating saving the UK more than 40 million tonnes of carbon emissions to date with its heating and cooling systems.

The Coventry-based company passed the milestone – the equivalent of the entire annual carbon emissions from Slovakia – earlier this month with the combined savings from its 200MW worth of installations.

The total has been run up since 2000 when GI Energy first pioneered the use of this extremely energy efficient method of heating and cooling buildings in the UK after founder Brian Davidson was impressed with the technology.

Since then GI Energy has installed systems in schools, hospitals, universities, supermarkets, commercial developments, district heating schemes, police headquarters and even a church. Flagship projects include One New Change in London and the Oxford Earth Sciences building for Oxford University.

Chris Davidson, Director of Development for GI Energy, said: “It is exciting to see just how big a contribution towards cutting the UK’s carbon footprint that GI Energy’s systems have already achieved - and there is more to come.

“Ground Source Energy Systems are fantastic both for cutting carbon footprints and for saving on energy bills. The underlying beauty of the system is that it effectively uses heat from the sun that has been stored naturally in the ground.

“For every kilowatt of power required to run a system, around four kilowatts of heating or up to six kilowatts of cooling is produced. It is a truly renewable form of heating and cooling which has a great future ahead of it.”

The Government has recently recognised the contribution that Ground Source Energy Systems can make by nearly tripling the Renewable Heat Incentive payments for Ground Source Heat Pump heating systems to up to10.2p per kWh of heat generated.

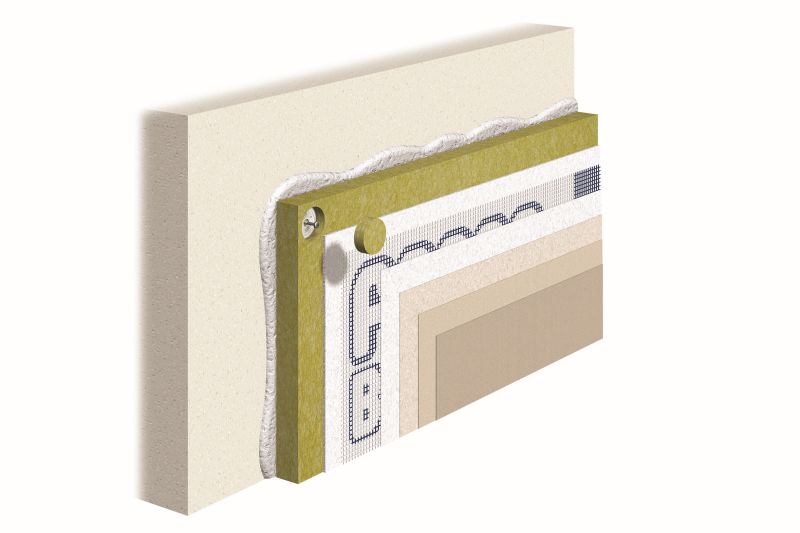

Ground Source Energy Systems comprise a network of pipes called “earth loops” buried underground and connected to a series of heat pumps. Liquid pumped through the loops extracts heat from the ground. It is then passed through the heat pumps which raise the temperature to a level suitable for central heating. For cooling, the system is used in reverse.

Sainsbury’s has embraced the technology, being the first customer to take advantage of GI Energy’s finance package that comes with a long-term repair and maintenance agreement, for installations at three stores, in Carlisle, East Kilbride and Rustington.

A host of high-profile installations are in the pipeline for GI Energy – at London Bridge railway station; Stonehenge visitor centre; Alder Hey’s Children’s Hospital in Liverpool; The Lexicon on City Road, which will be the highest skyscraper in Islington, London; and the Serpentine Sackler Gallery, a Grade II listed former gunpowder depot in Kensington Gardens, one of the Royal Parks.