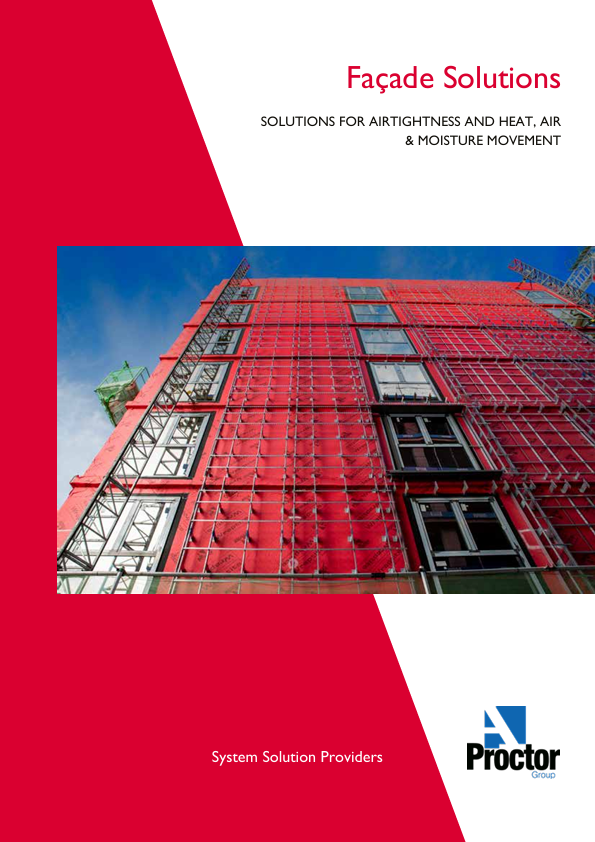

In its first year of operation, the new dedicated test centre for Wicona’s façade products – one of the first energy-positive industrial buildings in Europe – has generated 60 per cent more electricity than it needs for its own consumption.

Located at Bellenberg near the Wicona Brand Development Centre at Ulm in Germany, the €3.5m scheme provides in-house testing facilities for new products and project-specific façade solutions which can then be independently certified to the latest European standards.

The test centre is designed to be highly energy efficient and sustainable. Roof-mounted photovoltaic panels generate sufficient power for heating, lighting and operating the entire building, making it one of Europe’s first energy-positive production buildings.

Daily energy monitoring has shown that the building has generated enough energy to be self-sufficient and to deliver a significant level of electricity into the national grid. You can now track the energy performance of the test centre and monitor its power generation and consumption levels – see www.zeb-bellenberg.com.

A key factor in helping to reduce the energy consumption of the building to as little as 23kWh/m2a – around the same as a standard passive house – is its highly efficient Wicona façade. This is integrated with the building services and low energy technology, and is also highly glazed to allow most of the product testing to be carried out without the need for artificial lighting.

Other energy-efficient features of the new test centre include the use of heat pumps and a closed water circuit to minimise water consumption for the large volumes required for façade tests.

Commenting on the energy monitoring results for the past year, Bob Welsh, General Manager for Wicona in the UK, said, “This building, which showcases a Wicona façade, is designed to be highly sustainable as part of our ongoing commitment to minimising impact on the environment. The demand for façade solutions for zero energy and energy-positive building projects will continue to increase as a result of more stringent Building Regulations and the drive to further reduce carbon emissions – so this is a fantastic example of that in practice and what we can achieve with our own products and facilities.”

The in-house testing procedures and equipment for the building were developed by Wicona in conjunction with IFT Rosenheim (Institute of Window Technology), an independent accreditor. Facilities include:

Two façade test rigs allowing samples up to 10m by 10m to be rigorously tested under a full range of weather performance and safety conditions – air permeability, static and dynamic water pressure, wind and impact resistance

A testing rig for combinations of windows, doors and fixed light glazing with frame sizes of up to 3.6m by 2.9m, assessing air permeability, water tightness, and wind and impact resistance

A fitting rig to carry out performance tests on doors and windows up to 4m high, and their fittings and accessories.

With more than two decades of experience in complex and bespoke aluminium façades and 10 years’ on-site experience in the UK, Wicona offers a range of technically advanced façade systems which now includes unitised and stick curtain walling, structural and roof glazing, highly insulated window systems and heavy duty doors.

Wicona is also the first façade specialist to offer a complete turnkey service for the building envelope. From design concepts to fabrication, installation, testing and handover, Wicona and its partners will manage the full façade project, ensuring a seamless approach and offering detailed design and technical support for architects and contractors.

For further information about Wicona’s façade solutions for complex and bespoke projects, visit www.wicona.co.uk, email info.wiconauk@hydro.com or call 0845 602 8799.