A 1960s end of terrace house in central Oxford is being transformed into an ultra-low energy home.

Since August 2013 its owners, Tim Nicholson and Joanne Bowlt, have been installing a number of measures to save and generate energy, whilst remodelling the interior to create a stylish and comfortable family home.

Installing green technologies within new build properties is now common practice, however retrofitting these technologies within existing homes presents some tremendous challenges.

Tim Nicholson says: "There are 25 million houses in the UK and 80% of these will still be around by 2050 by which time they need to be zero carbon. We are trying to do our bit, exploring what can be done in an ambitious way. However, whilst energy efficiency is an important goal, it is not the only one."

New walls were built to the side and rear of the four bedroom house, to form a second insulated cavity. It has triple glazed windows, uses solar PV panels to generate electricity and solar thermal panels to generate hot water, it has mechanical ventilation with heat recovery, LED lighting and a wood burning boiler stove plus eco showers and taps.

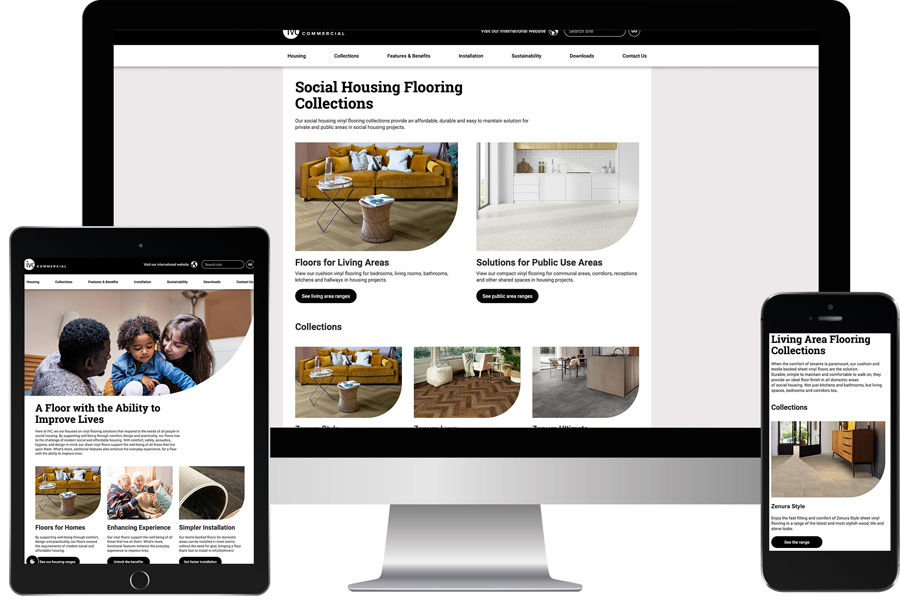

Sustainability and aesthetics were the key criteria when it came to choosing the materials used in this project and Tim Nicholson has installed Moso Bamboo Flooring throughout the ground floor - including the open plan kitchen, dining and living room - above the underfloor heating system.

"The sustainability of bamboo and the speed at which it grows were an important factor, plus it looks great and is extremely hardwearing," says Tim Nicholson.

Moso Bamboo Surfaces supplied their Bamboo Elite flooring for this project. Three layers of bamboo are strand woven and cross pressed for extra stability.

Rob Wooldridge, Commercial Accounts Manager at Moso Bamboo Surfaces says: "This was the ideal material for the project as it is extremely durable and more stable than most hardwoods, so will not shrink or warp even above an underfloor heating system."

Moso’s 20mm 3ply plain pressed caramel plywood panels have also been used on the kitchen doors and drawer fronts as well as in the bathroom and shower rooms with plans to make shelves and cupboards in the dining room from the same material.

Tim Nicholson’s home is proof that green technologies and aesthetics can be successfully combined. “Everyone wants a home for their family that’s really warm, comfortable and appealing,” says Tim. “I also want to help the planet, but I don’t want to have a miserable existence where I’m a slave to the woodburner or suffer cold showers! I hope our home proves that being eco-friendly can be an attractive way of living.”