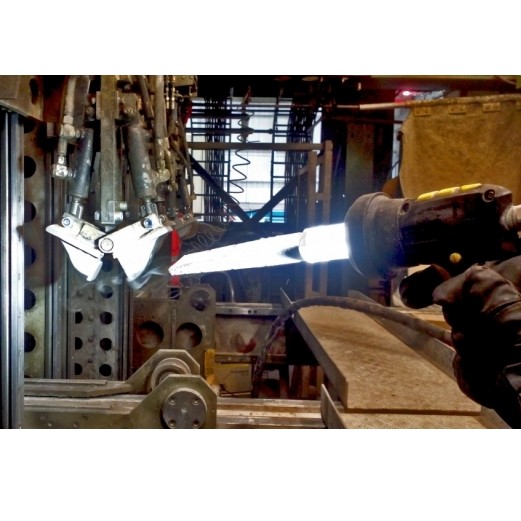

The UK’s leading precast concrete manufacturer, Bison Manufacturing, has invested in a new environmentally friendly system to clean its factory machinery.

In line with Bison’s ongoing efforts to lower its environmental impact, the precast manufacturers required a new system to use in place of their traditional water pressure washers, which can produce large amounts of waste which can be difficult and costly to dispose of.

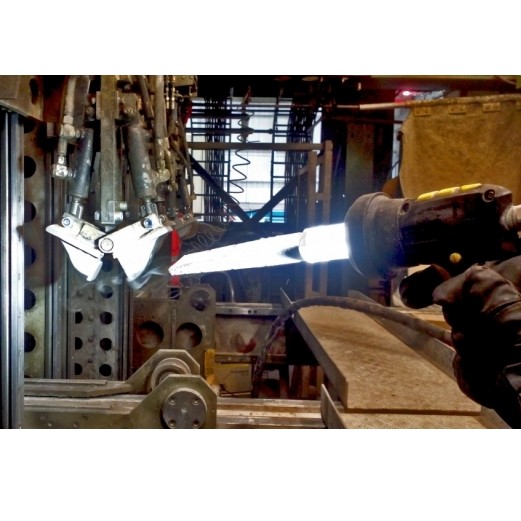

The new system from Karcher, a company known for their pressure washers, uses dry ice pellets to clean concrete residue off machines without the use of any chemicals or spray agents.

Starting as solid carbon dioxide, when exposed to room temperature and used with pressure, the pellets transition into a carbon dioxide gas, leaving behind no residues such as abrasives or waste water.

Bison’s Sales and Commercial Manager, Mike Nelson said: “We have been working hard to find a replacement for our traditional water pressure washer. Although this has not caused any major issues for us in the past, we want to ensure that our factory is working to maximum efficiency whilst also being sensitive to the environment.

“When we came across the dry ice system, we instantly knew it would suit us. The cleaning was quick, dry and produced hardly any waste, which will assist us in increasing productivity.”

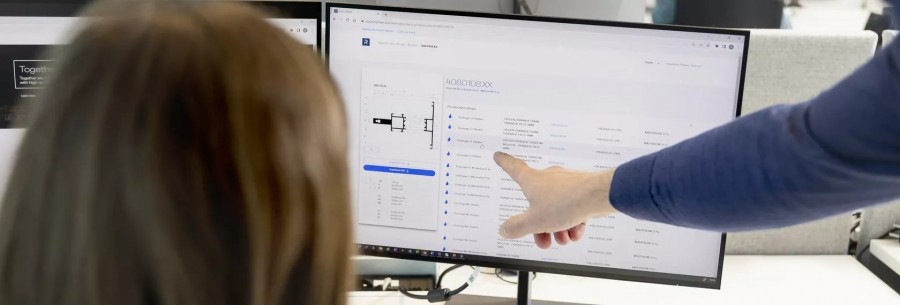

Bison has also invested in a new unit plotter, a machine used to paint concrete units that are still in the wet stage with details of the products, including the unit’s width, length and shape, as well as contract specifics.

By providing factory operators with this information the unit can be completed in the wet stage, without the requirement for it to undergo further production processes, helping to accelerate manufacturing times.

Mike Nelson added: “At Bison we are constantly looking at ways to improve our processes. The new unit plotter means our units can be manufactured and delivered to site more quickly, giving contractors and developers confidence that their projects will meet the required timescales.”