Sika supplied the hard-wearing,

moisture-resistant floor to ensure a pharmaceutical plant is safeguarded

against potential damage and working hours being lost due to flooding.

The Smith and Nephew manufacturing facility based in Hull specialises in the production of medical equipment used in advanced wound management. Located beside the River Humber, the three-storey building’s basement has previously been flooded, with damp and moisture also causing damage to the higher, ground floor which houses a laboratory and sensitive testing equipment.

During a recent refurbishment of the ground floor, contractors Zircon Flooring required a floor which was able to withstand the long-term rigours of heavy machinery usage as well as demonstrating excellent resistance to damp and moisture in the event of future flooding. Sikafloor provided the ideal system to satisfy both requirements.

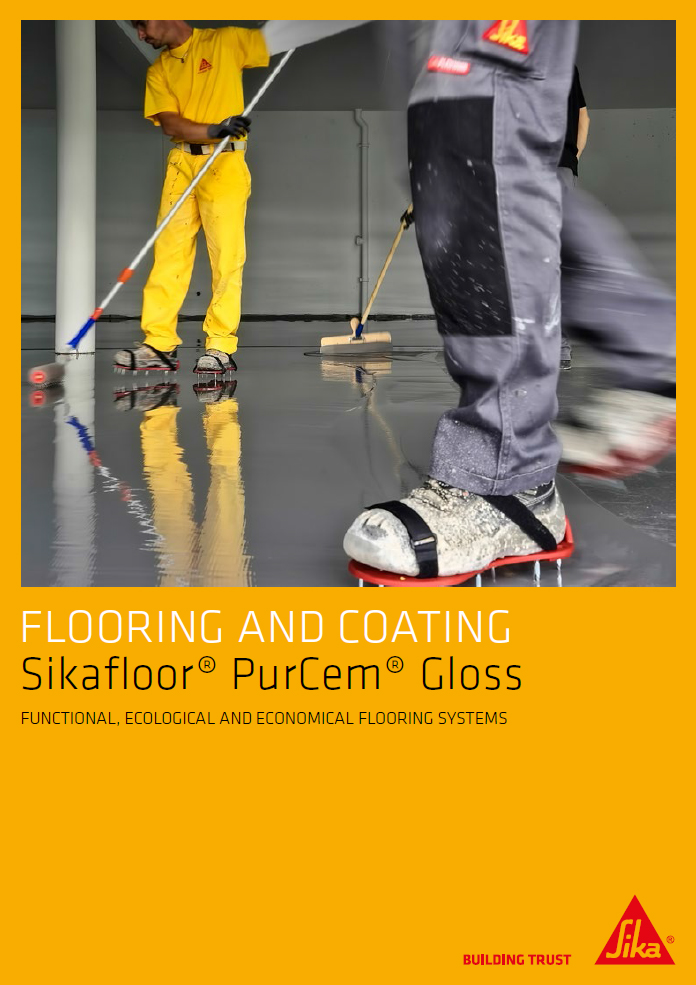

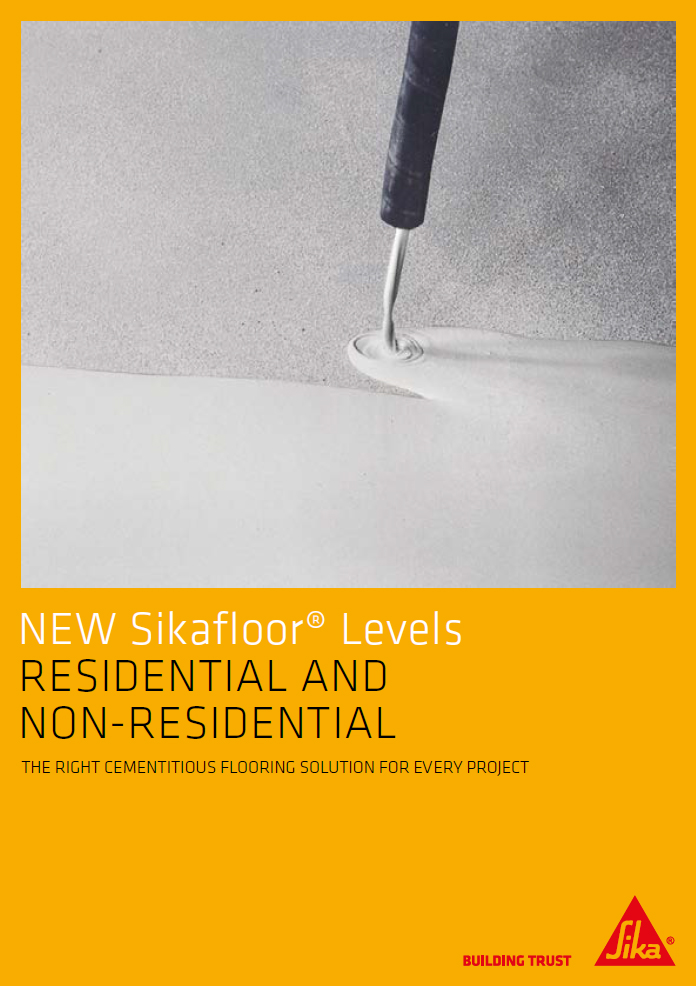

With work on the floor’s refurbishment starting in November 2016, the contractor’s initial challenge was to remove the existing bitumen surface which required a jack hammer to lift due to its viscous consistency. Once removed, Sikafloor®-81 EpoCem®, a three-part, epoxy-modified, cementitious, fine-textured mortar was applied.

Suitable for self-smoothing floor screeds in thin layers of 1.5mm to 3mm – the Smith and Nephew project required the installation of a floor with a level tolerance of between 0.5mm and 5.0mm – Sikafloor®-81 EpoCem® not only helps create a superbly-level floor, it offers excellent moisture control. Fast-setting Sikafloor® Level-30 was then applied.

The polymer-modified, pumpable cementitious screed provides higher thickness for interior or outdoor floors, meeting the requirements of class R3 according to EN 1504 – 3, with a walk-on time of between three and four hours. Sikafloor®-327 provided the next layer - a solvent free, self-smoothing PUR resin with good mechanical and slip resistance. For the final coat, Sikafloor®-305 W, a two-part, water-based, low VOC, polyurethane, easy-to-clean, coloured matt seal coat, was applied.

Stewart Draper, Managing Director at Zircon Flooring, said: “The Sikafloor system made for an extremely comfortable and effective installation. It meant we easily achieved the client’s required flooring level tolerance, as well as supplying a hard-wearing, moisture-resistant surface that will remain safe and dry for years to come.”

The ground floor’s surface refurbishment was completed in March 2017. With Sika’s technical teams, who were in attendance at various times during the application, giving it their seal of approval in the form of a 10-year warranty. It means the client has full peace of mind that the floor has been installed to Sika’s exacting standards and will stand the test of time despite its proximity to the River Humber and its fluctuating, and sometimes, damaging tide.