When approached to work on a large residential new-build housing project in Walthamstow, leading waterproofing and roofing expert, Langley Waterproofing Systems Ltd was on-hand to provide the ideal solution with Approved Contractor, T & T Roofing Limited.

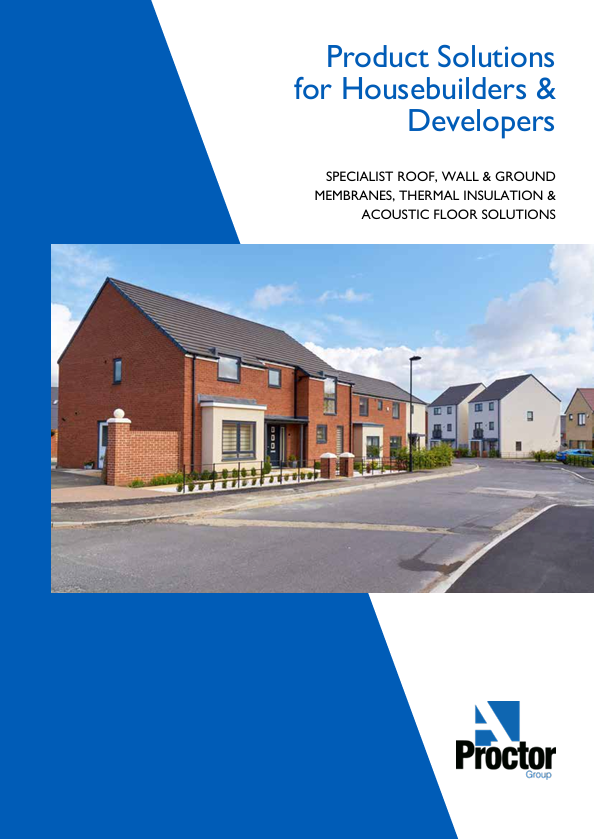

Walthamstow continues to be the centre of a large-scale modernisation and renewal strategy. Taylor Wimpey is one, of several developers, working to turn the former industrial area of Blackhorse Lane into a vibrant community that will attract a new generation of residents and businesses.

As a part of the ambitious regeneration, Taylor Wimpey’s Eclipse development on Blackhorse Lane will deliver 499 one, two and three bedroom apartments across three phases. Each block features innovative green roof spaces over both affordable and private properties.

Building pressure for national housebuilders to meet the targeted number of new build homes continues to increase year on year. Latest information included within a Commons Library Briefing (March 2020), now estimates the number of new homes needed in England is up to 345,000 per year. In 2018/19 the total housing stock in England increased by approximately 241,000 homes, and although this is 9% higher than the previous year, it is still lower than estimated requirement.

On phase three of the development, Taylor Wimpey needed a supplier and trusted roofing contractor team that could reliably respond to the demand of delivering system installations swiftly. This project contributed towards achieving the defined number of new homes needed for the local area. To this end, it was important that the roofing system specified could reliably be installed swiftly to help meet this requirement.

Speaking on the decision to choose Langley’s roofing system solution, Ryan Gow, Externals Site Manager at Taylor Wimpey, commented: “The huge scale of the Blackhorse Lane development presented several challenges that we needed to overcome. For the roofing, we needed speed of installation without compromising quality and durability. We were impressed with Langley’s HM-40 Paratech Hot-Melt Roofing System performance. As this was the third phase of the development space was a critical factor, it was therefore important that deliveries were closely managed to avoid delays to the build schedule. Langley ensured that this was always the case, so that delays never occurred.”

Langley’s innovative HM-40 Paratech Hot-Melt Roofing system offers a number of features and characteristics that made it the ideal choice. Unlike other hot melt solutions, which tend to use fleeces, the Paratech system incorporates a reinforcement mesh allowing the system to be rolled out and thus making installation quicker.

Speaking on the installation process, Thomas Peebles, Managing

Director at T & T Roofing Limited, a Langley Approved Contractor,

commented: “The features of the HM-40 system provide a seamless,

issue-free, roof installation, with minimal disruption and speedy

install times. Langley’s technical team is always on-hand to provide

assistance when necessary, working collaboratively to guarantee a

consistent and high-quality installation.”

The HM-40 Hot Melt

Roofing system has been specially designed for new-build projects,

particularly where a fast install and fully bonded system is required,

meaning further trades can access the area. As such, the solution is

primarily used for concrete substrates, but can also be used on plywood

and for a warm or cold roof configuration. As well as offering quick

installation, the solution can be used for weatherproofing for green

roofs, terraces and podium decks.

Additionally, when

installed by an approved contractor, the HM-40 system provides up

40-years durability. To this end, the system also meets NHBC Technical

Standards Chapter 7.1 for roofs and balconies and its performance has

been certified by the British Board of Agrément (BBA).

Speaking

on the specification of the HM-40 Hot Melt Roofing system, Chetin Ali,

Area Manager at Langley commented: “The solution used at Blackhorse Lane

perfectly encapsulates what sets us apart. As with all our projects, we

provided the project team with a full holistic package, which includes

technical and design advice, specifications, site monitoring, reporting

and warranty inspections. The monolithic, elastomeric waterproofing

system is long-lasting and has incredible tensile strength. Its rapid

drying solution means it can be quickly accessed by following trades

on-site. It also enables rapid installation, which was a big benefit on

this project.”

Ryan

Gow concluded: “We were thoroughly pleased with the waterproofing

solution and how efficiently it could be installed. The 40-year warranty

that is included to cover both the materials and workmanship, provides

us and the new homeowners at the development with peace of mind and the

quality of construction we pride ourselves on.”

The majority of

the development is now complete, with the final homes due for completion

in 2020, and a new community is developing as more residents move in. T

& T Roofing Limited was awarded Langley Contractor of the Month in

March 2019, for its extremely high standard of work on the project.