Overview

Famed for hosting some of the biggest names in the entertainment industry such as The Beatles, The Rolling Stones, Morecambe and Wise, The Bee Gees, Roy Orbison, T-Rex and Shirley Bassey to name but a few, the Stockton Globe was once an iconic venue.

Whilst the theatre played host to these world-famous bands, it was also a cinema and showed the very first 3D film in the region, in 1953.

The Grade II-listed, Art Deco theatre closed in 1997 having been used as a bingo hall for the previous 20 years.

Spring 2020, will see the Globe re-open this time as a nationally renowned, 3,000 capacity live entertainments venue.

Many of the original ornamental features have survived and the Theatres Trust have described the Grade II-listed building as "an excellent example of its kind".

Work to refurbish Stockton's Globe Theatre beginning in 2011, but the renovation has been dogged by structural issues, including the discovery of unsupported walls, rotting timbers and a weak roof.

Delta’s Technical Team along with Delta Registered Installers Marsden Damp Services were approached by the main contractor Wilmott Dixon to give assistance on designing a robust waterproofing solution. Working in collaboration with the architects and project team, this team of waterproofing experts were easily able to offer a simplistic and practical approach.

Methodology

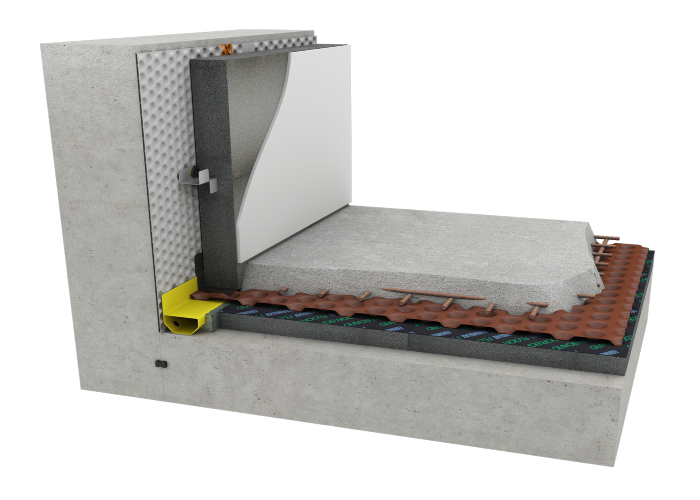

The project was split into 2 phases with Phase 1 waterproofing the existing stage and orchestra pit and Phase 2, the seating and ancillary rooms which all required the installation of a Type C waterproofing system to ensure a Grade 3 habitable environment was created.

Type C waterproofing systems being the most reliable and maintainable approach to the project were incorporated into the BS8102:2009 structural waterproof design. Before installation of the Delta Type C membranes, all existing walls and new concrete slab were treated with Koster Polysil TG 500 anti-lime inhibiter to seal the surfaces and reduce the leaching of ‘free lime’ which could cause blockages behind the membranes.

The principles of a Delta Type C cavity drainage system are to allow moisture or running water to travel behind the membrane within a controlled channelled drainage system. Any water ingress is collected and discharged via a suitable sump pump. To ensure the Type C system was fully maintainable, inspection ports were located at every major change of direction. All floors and drainage elements were tested to ensure these would drain as the system was designed and BS 8102:2009 requirements were met.

Delta MS500 and PT mesh membrane 8mm cavity drain membranes were used for the waterproofing of the walls. The Delta MS500 was fixed using Delta Qwik-seal plugs, fixed at 600mm centres with added benefits of Delta double-sided butyl tape to seal joints and overlaps. Delta butyl Corner strip tape was added to seal wall/floor joints. Delta MS20 20mm cavity drain membrane was used for waterproofing the floors. This is a heavy gauge version and incorporates 20 mm studs which offer extra drainage capacity. Delta MS20 was used as a “cavity former” for this type of new construction. The Delta MS20 is neatly rolled out across the basement floor; the sheets are overlapped and sealed in accordance with the manufacturer’s instructions. Corner strip tape was added to seal wall/floor joints.

Products Used

Koster Polysil TG500

Delta MS500 / PT

Delta MS20

Delta Tape / Cornerstrip

Delta Qwik-Seal Plugs

Delta Drainage Channel

Case Study Results

Stockton’s Globe Theatre has been transformed from an unused derelict building back to its former glory for many theatrical and musical performances to be enjoyed once again. By incorporating a Delta System, the theatre is completely protected against water ingress along with Delta’s tested product life cycle and installation by Delta Registered Installers that the project easily complied to British Standards.