A Government-backed innovation and demonstration programme has successfully developed and trialled new low carbon cements which have up to 60 per cent lower embodied CO2 emissions than Portland Cement, the current market leader in the UK.

Research supported by the Department for Business, Energy and Industrial Strategy (BEIS) led by the Mineral Products Association (MPA) reveals that if the new cements are fully adopted in the UK, up to four million tonnes of direct CO2 could be saved every year - the equivalent of taking 2.2 million cars off the road.

During the two-year Carbon Trust managed Industrial Energy Efficiency Accelerator (IEEA) project, concretes containing 22 low carbon multi-component cements were extensively tested for their durability and performance.

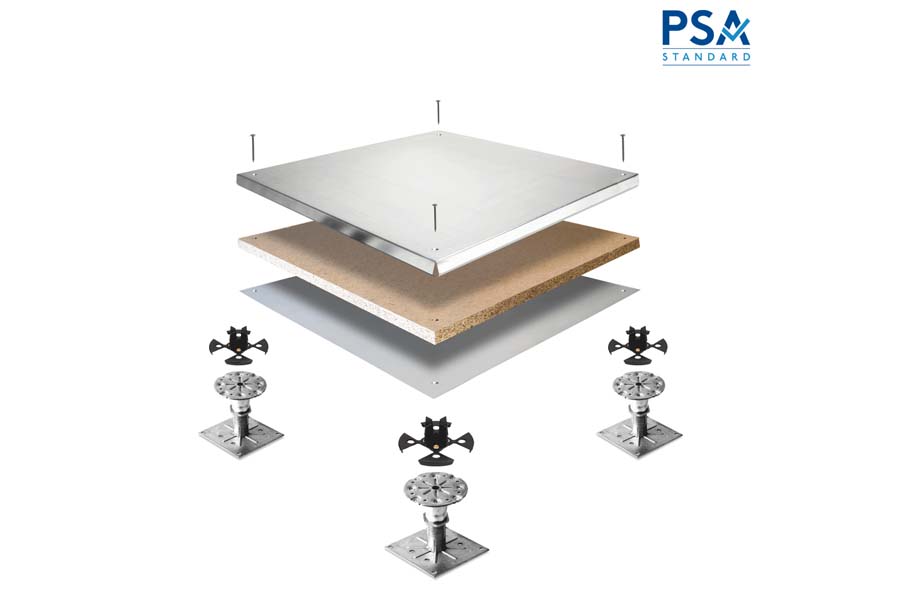

Cements for UK concrete production generally consist of two main components, which are usually Portland cement (CEM I) and limited quantities of either fly ash, GGBS or limestone powder. In this project, multi-component cements with three main ingredients were developed: CEM I-fly ash-limestone powder, and CEM I-GGBS-limestone powder.

Currently 79 per cent of UK factory-made cement market sales are CEM I, with a total market of around 10 million tonnes per annum.

This research, robust laboratory testing and practical demonstration has shown that the new multi-component cements can be much lower in CO2 whilst matching the durability and performance of the construction industry’s most popular cements

As part of the BEIS IEEA project, the MPA has recommended to the British Standards Institution (BSI) that these new cements should be included in the UK concrete standard (BS 8500), to help designers, specifiers, contractors and the wider construction sector reduce emissions related to the built environment.

Dr Richard Leese, MPA Director – Industrial Policy, Energy and Climate Change, said: “This is a huge step forward in the delivery of the UK concrete and cement industry’s roadmap to beyond net zero. These new cements have the potential to accelerate real environmental savings for construction projects and complement the sector’s wider decarbonisation programme.

“Following adoption in the British Standard it is important that designers and contractors understand that these are commercially viable materials, tested on UK construction sites with the proven ability to save embodied carbon now.”

Minister for Industry Lee Rowley said: “The UK is committed to reducing emissions across all sectors, including construction, and development of these low-carbon cements can have a significant impact in making a vital construction material cleaner and greener.

“Supported by the government-funded Industrial Energy Efficiency Accelerator programme, the MPA project is a great example of how the UK’s innovators are leading the fight against climate change.”

Paul McKinney, Associate Director and IEEA Programme Manager at the Carbon Trust added: “We are really pleased by the success of the MPA’s Industrial Energy Efficiency Accelerator project. This is a great example of an industry working together to reduce its carbon footprint, contributing to the journey towards net zero. The manufacture and rigorous testing undertaken for a wide range of low carbon multi-component cements will hopefully soon lead to recognition within the relevant British Standard, leading to widespread uptake across the UK construction sector.”

UK Concrete, part of the Mineral Products Association (MPA), has identified that a net zero UK concrete and cement industry can be delivered through decarbonised electricity and transport networks, fuel switching, greater use of low-carbon cements and concretes as well as Carbon Capture, Use or Storage (CCUS) technology for cement manufacture.