The Building Engineering Services Association (BESA) has launched a new specification for ventilation hygiene as part of its ongoing efforts to minimise the risk posed by contaminated indoor air to human health and well-being.

It has also updated two of its air hygiene training courses to ensure delivery against the new specification and improve safety standards in buildings. The courses are designed so that contractors can advise their clients about ventilation cleanliness to help them meet health & safety obligations and comply with increasingly stringent legislation.

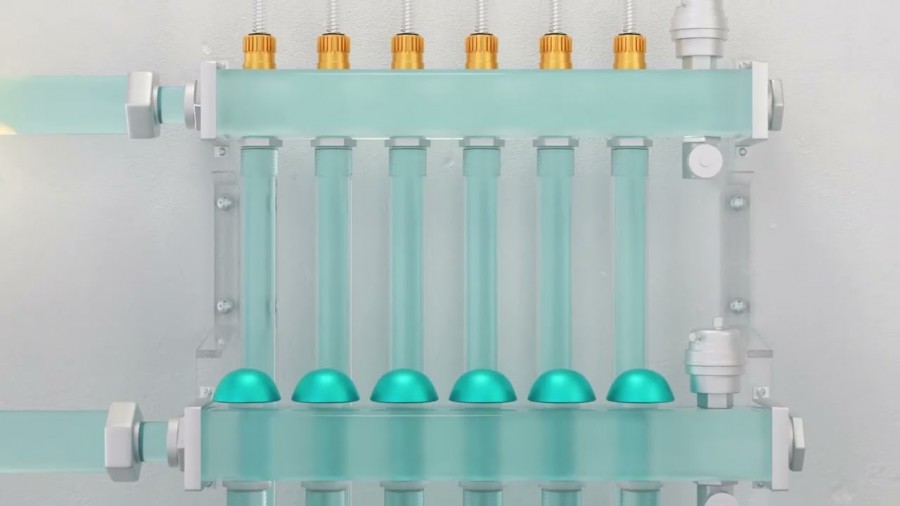

The Association said that TR19 Air ‘Specification for internal cleanliness and hygiene management of ventilation systems was designed to address an “urgent need for better cleaning and maintenance of ventilation ducting”. This has been highlighted by healthcare professionals as vital for reducing building occupants’ exposure to harmful airborne particulates and pollutants.

The Covid-19 pandemic also raised awareness of the role of effective ventilation in reducing the spread of disease in indoor spaces and prompted a dramatic rise in the level of air quality monitoring.

“Employers and building managers have an obligation under health & safety legislation to ensure the indoor environment is safe and does not pose a risk to the health and well-being of workers and visitors,” said BESA technical director Graeme Fox.

“Cleaning ventilation ductwork has often been considered one of those ‘out of sight out of mind’ tasks that can be postponed or avoided entirely to reduce cost, but the pandemic proved just how risky that strategy is.

“This new specification is a big step towards revolutionising air quality in buildings and it will help building owners and managers meet their obligations and remain compliant with legislation.”

The new TR19 Air Hygiene Operative course will provide training on cleaning ventilation systems to the required standards with operatives having to complete both theory and practical tests.

The second course, Air Hygiene Technician, is for those who, as well as cleaning, must also be able to produce risk assessments/method statements (RAMS); install access panels, and inspect, test and report on the cleanliness of the system.

TR19 Air is the latest update to a specification first developed by BESA in 1991. This was updated as TR17 in 1998 to establish standards for testing, cleaning, and verification of the internal cleanliness of ventilation systems.

The original TR19® guide to good practice for the ‘Internal Cleanliness of Ventilation Systems’, was then produced to cover all aspects of ventilation cleanliness in a single document. However, following several revisions to what quickly became the industry’s primary specification, a separate document ‘TR19® Grease’ was published and focused on the fire risk management of grease accumulation in kitchen extraction systems.

This was developed to help address the specific risks to people and property posed by poorly maintained systems in commercial kitchens, highlighted by fire officers up and down the country.

With this new document, BESA is responding to growing demand for another targeted specification focused on the specific cleaning requirements for air ducts. TR19® Air is also part of a wider campaign to improve indoor air quality (IAQ) in buildings and address the threats posed to human health by airborne pathogens and particulate matter.

“Poorly maintained, dirty air ducts cannot provide the level of air quality needed to safeguard human health and well-being in buildings,” said Fox. “Ventilation management is also at the heart of the challenge to reduce energy consumption and prolong system life in line with wider carbon reduction goals.

“Accumulated debris in air ducts can obstruct the airflow, forcing fans to work harder to maintain the desired temperature and air change rates. Cleaning will allow the system to operate more efficiently and reduce wear and tear. This will also be an increasingly important consideration when retrofitting buildings to achieve net zero.,” he said.

Cleaning the ventilation also reduces unpleasant smells and the risk of mould and condensation. Moisture in the ductwork encourages the growth of fungi, which releases spores into the air that can cause or exacerbate respiratory problems and allergies.

BESA also pointed out that insurance providers were taking a keen interest in this area and adjusting their premiums to reflect the level of risk created by poor building management.

TR19 Air costs £75 for BESA members and £150 for non-members. Anyone booking onto one of the training courses will also receive a free copy.

It covers all relevant legislation and professional guidance, including BSEN15780 ‘Cleanliness of Ventilation Systems’, which has been the British and European Standard since 2011.

The specification also reflects the aspirations of the first British Standard for Health and Well-being in Buildings British Standard 40102 (Part One), which was published this year and provides recommendations for measuring, monitoring, and reporting indoor environmental quality (IEQ) in non-domestic buildings.

BESA’s new specification can be applied to new construction, upgrades and retrofits, and the regular maintenance of ventilation systems. It is useful to building operators, occupants, specifiers, and consulting engineers as well as specialist contractors.

TR19 Air can be downloaded from the BESA website