In the creation of unique and impactful architectural design, architects need to have the tools to be able to break free from traditional building materials and techniques. It’s why the partnership between architects, contractors and engineers is crucial in realising the very best in creative design. But what happens when projects become too complex for standard solutions? Mick Beresford of Leviat says the answer lies in specialised engineered solutions and explains why product manufacturers can play a vital role in turning architectural ambition into reality.

Today’s built environment has become a showcase to not just the conventional but also increasingly daring designs; buildings that will challenge our perceptions of space, form and function. This ambition may manifest itself in designs featuring unusual or irregular angles, intricate façades, and seamlessly integrated curved structures. These architectural statements present complex technical challenges that go beyond conventional building methods. This is where specialist product manufacturers step in, bridging the crucial gap between creative vision and structural feasibility.

Innovation in action

By creating bespoke engineered components, these manufacturers play an important role in achieving the most complex architectural designs. Through early involvement, they can tailor their products to the specific requirements of each project, enabling architects and contractors to push the boundaries of what is possible in construction. These engineered solutions transform architectural concepts into tangible, safe, and visually striking buildings. Their ability to adapt standard products or create bespoke solutions ensures even the most challenging designs can be realised without compromising on structural integrity or aesthetic appeal.

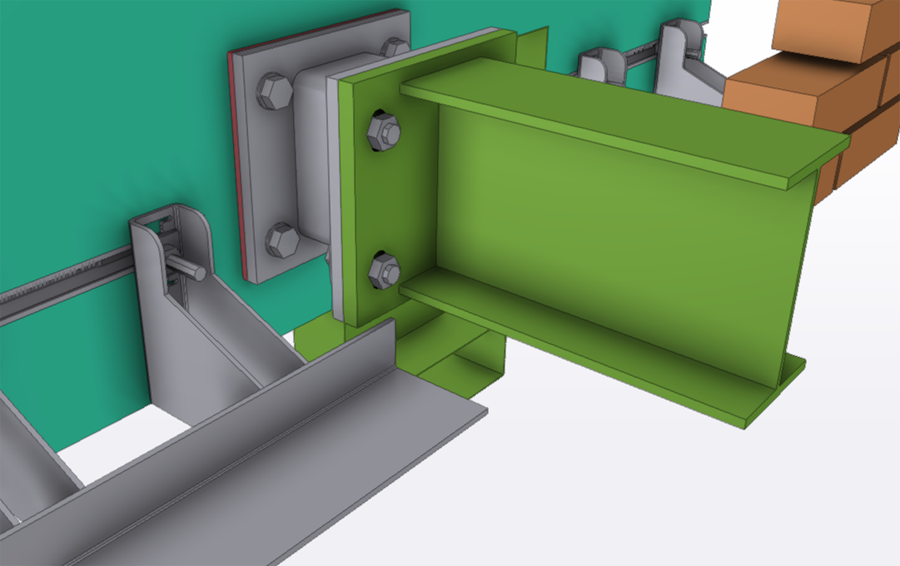

This adaptability is particularly evident in two critical areas of modern building design: masonry support systems and balcony connectors. These vital components, while often hidden from view, are fundamental in realising some of the most striking features of contemporary architecture.

Reimagined façades

By providing hidden structural support for brick or natural stone, masonry support systems make façade designs possible. These systems can be engineered to accommodate unusual angles, cantilevers, and curved surfaces, so that architects can break free from the limitations of standard brick-and-mortar construction.

Masonry support systems can be adapted to unique structural conditions, such as post-tensioned slabs or heavily reinforced concrete, ensuring that the architectural intent is preserved even in the face of complex engineering requirements. Differential movement, corrosion resistance, type of cladding and frame type, all need to be considered. Furthermore, advanced modelling and fabrication techniques offered by manufacturers ensures the seamless integration of support systems within the building structure.

Whether it's a subtly undulating wall or a dramatically cantilevered feature, engineered masonry support solutions ensure that the vision can be realised without compromising on structural integrity or long-term durability.

Balcony connectors

Beyond the façade, balconies have become integral elements in aesthetically appealing, mixed-use developments. However, integrating these features seamlessly into a building's structure, especially in high-rise or unusually shaped buildings, presents significant engineering challenges.

Engineered balcony connector solutions address these challenges head-on and their correct specification is crucial for ensuring structural integrity, thermal efficiency, and fire safety. Balcony connectors are that critical link between the balcony and the building structure, transferring loads and accommodating potential movements. By offering thermal break technology and adjustable fixing points, these connectors allow architects to design balconies that appear to be natural extensions of the building's form, rather than afterthoughts.

Building on the curve

The way that innovative engineering solutions can bring complex architectural visions to life is exemplified in the Shoreline development in Folkstone. It’s distinctive curved design, featuring convex and concave elements and a glazed white brick façade, presented unique challenges for masonry support and balcony integration.

The project demanded custom-designed masonry support systems to realise the building's curved structure. Leviat’s technical engineers developed bespoke brackets and channels to support the masonry and precast brick soffits, carefully coordinating with window locations at every level. Special fabrications were created for acute corners, ensuring seamless integration with the unique geometry.

The balcony connectors required equally innovative solutions. Non-standard brackets were designed to connect steel balconies to the curved concrete frame, navigating potential clashes with reinforcement in the congested slab edge. This process demanded close collaboration between design and production teams. Another important factor was the coastal location which necessitated components being manufactured using grade 316 stainless steel to withstand sea spray and harsh environmental conditions.

Collaborative approach

What emerged from this project is the value of early engagement and close collaboration between architects, engineers, contractors and manufacturers to overcome complex design challenges. The result being a structurally sound and visually striking building.

Whilst the contributions of product manufacturers may sometimes be limited to a narrow technical aspect of an overall building, their involvement from the very start of a project can make a significant impact. When manufacturers are able to engage with architects and contractors from the initial design stages, then their specialised engineered solutions can be tailored to a project’s requirements and push the boundaries of what is possible when it comes to design.

For more information please visit: https://www.ancon.co.uk/projects/residential/shoreline-crescent-folkestone