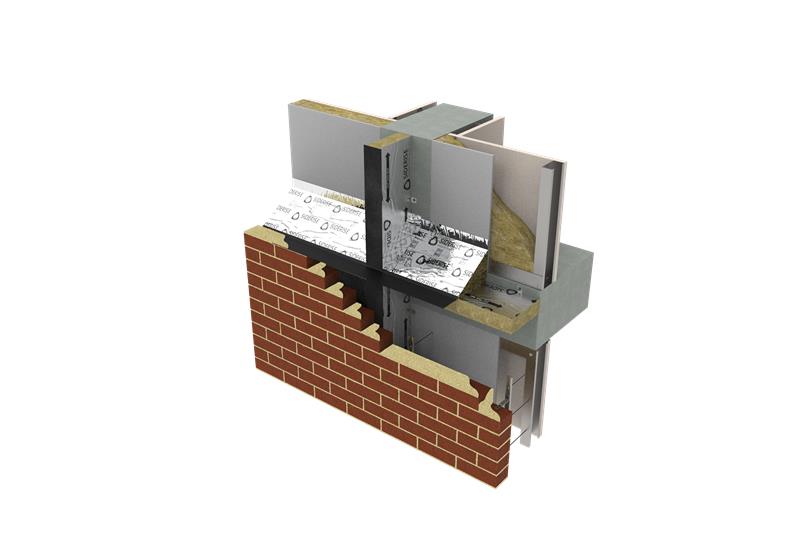

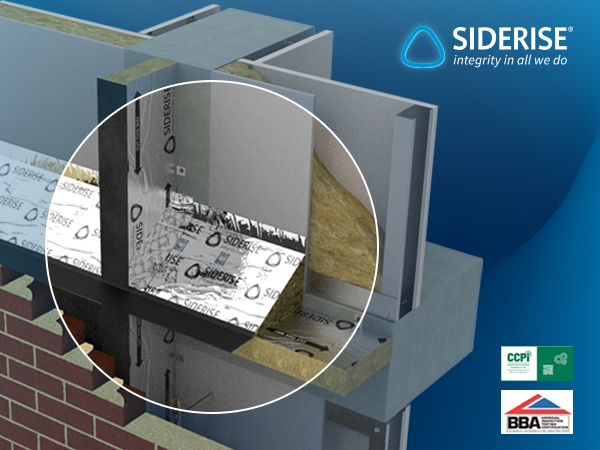

Cavity trays installed within steel-framed masonry walls in high-rise residential and other ‘relevant buildings’ must achieve an A1 or A2-s1, d0 reaction to fire classification to:

- comply with the requirements of Regulation 7(2) as outlined in Approved Document B (England and Wales); and

- ensure they do not contribute to fire propagation within the enclosed wall cavity.

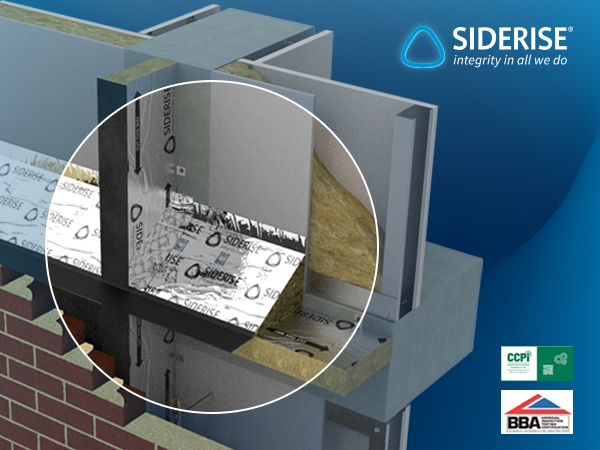

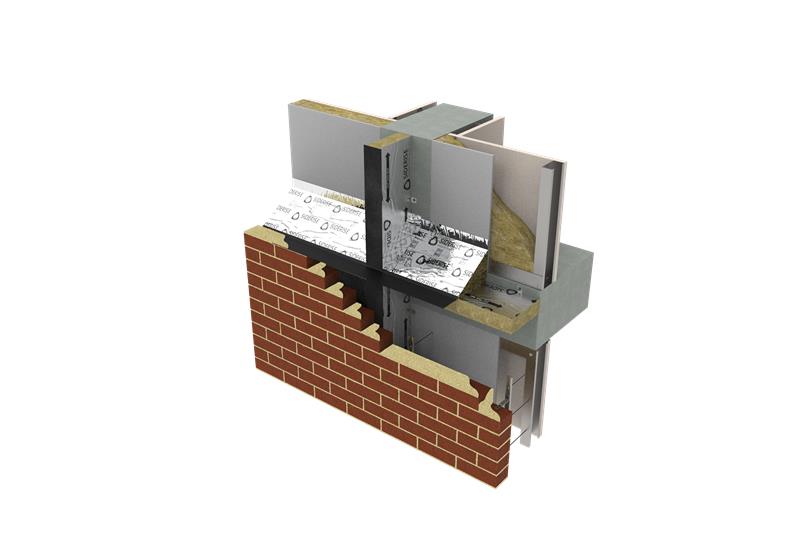

Siderise CT Cavity Tray was engineered by passive fire protection experts to specifically meet these requirements, providing a compliant moisture management solution that complements a building’s passive fire safety strategy. It combines a flexible aluminium tray with integral A1-rated stone wool insulation to create a durable and robust factory-assembled product that provides reliable quality with several key benefits:

Tested performance

Siderise CT Cavity Tray has an A2-s1, d0 reaction to fire classification to EN 13501-1: 2018 that applies to the complete pre-formed section rather than just its component parts. For further assurance that the product is fit for purpose, it has undergone rigorous BBA testing and certification, including assessing joint water tightness, mortar adhesion, material durability and practicability of installation. It can also comply with the technical requirements of major warranty providers such as NHBC, Premier Guarantee and LABC.

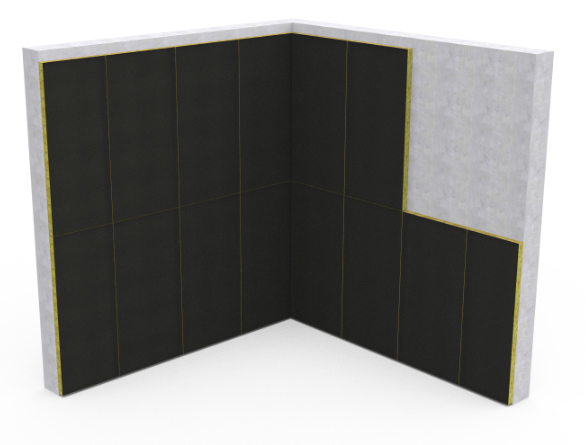

Complements performance of firestops and cavity barriers

Sourcing a compliant cavity tray solution from a passive fire protection manufacturer also means that it can be specified alongside Siderise EW cavity barriers or firestops, which work hand in hand d for holistic compatible performance, as well as ease of logistics. Siderise CT Cavity Tray is just one of the solutions Siderise has developed and tested specifically for masonry constructions.

Simpler detailing

The traditional method of using site formed rigid metal trays can present difficulties when detailing complex areas such as external corners, around windows and ends. Siderise CT Cavity Tray offers a much simpler approach, allowing these complex areas to be addressed by cutting the cavity tray at the correct angles and sealing the joints with a specially formulated foil sealing tape, ensuring integrity.

Reliable onsite quality

Siderise CT Cavity Tray is quicker and easier to install than solutions formed onsite with rigid materials in segregated workshop zones. Arriving to site as pre-assembled lengths, it simply requires a cutting knife and sealing tape— with no need to add additional insulation or use sealants.

This speed of build can have a considerable impact on project schedule efficiency, especially on larger projects with multiple floors and where different trades such as bricklayers need to share masts.

Explore the product.