Performance in high pressure refrigeration applications is vital and Conex Bänninger’s high strength copper alloy K65 fittings provide a safe, simple and economical solution up to 130 bar.

Developed in conjunction with Wieland, the global leader in copper alloy tube production, K65 was created in response to the increased demand for CO2 R-744 in commercial refrigeration applications, and in particular supermarkets.

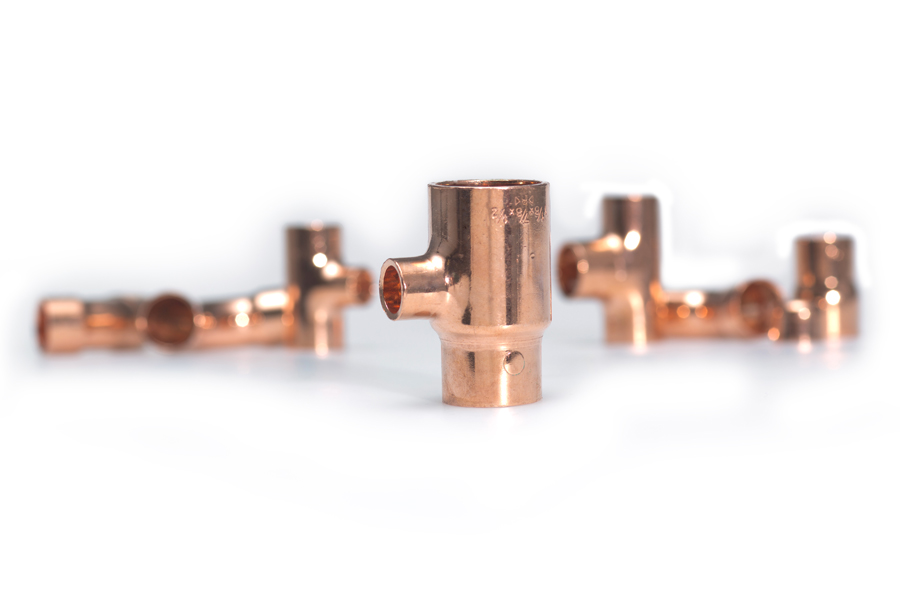

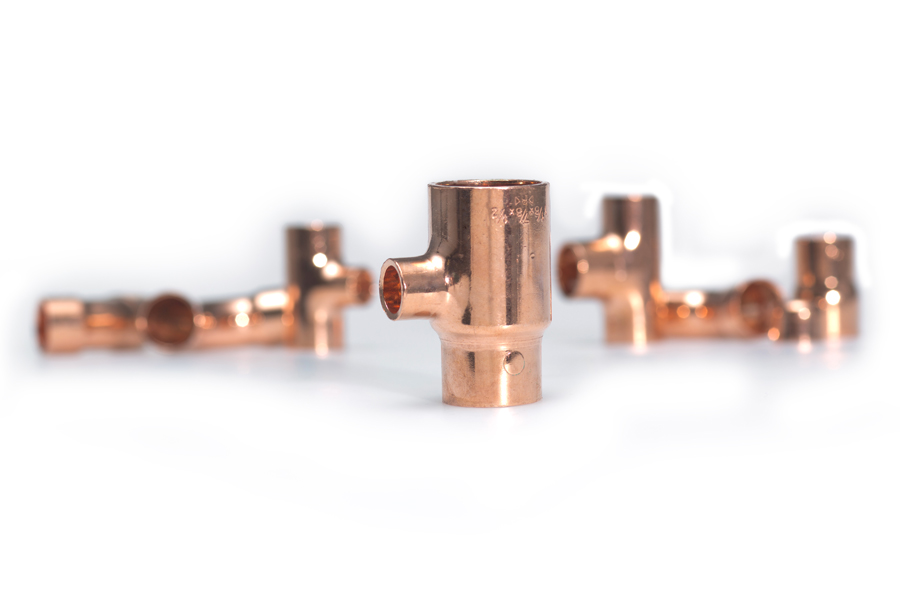

With the markets phasing out high-GWP refrigerants, Conex Bänninger’s K65 braze system utilises quality materials to become the installers choice for high-pressure refrigeration applications. The product is much lighter, making it easier to cut and much quicker to transfer to site compared to steel alternatives. It is available in a wide range of fittings from 3/8” through to 2 5/8”.

Standard copper pipe can’t withstand the required 130 bar. K65 bridges the gap by offering a lightweight, easy-to-braze (no welding required) copper-iron alloy that is specifically engineered for the rigours of high-pressure CO₂ systems.

CO2 has zero ODP (Ozone Depletion Potential) and a GWP (Global Warming Potential) of just one. K65 is readily identifiable and easy to distinguish from traditional copper due to its slightly magnetic property, the K65 and 130 bar markings. When professionally installed K65 fittings are covered by a twenty-five-year guarantee.

For further information on Conex Bänninger’s products, visit www.conexbanninger.co.uk