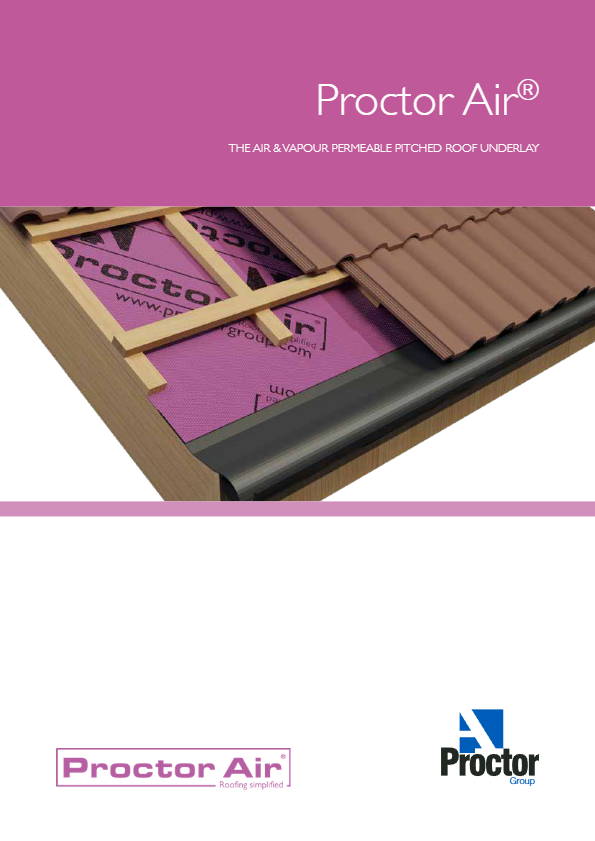

Proctor Air® is an air permeable low resistance (APLR) underlay for pitched roof applications.

While the majority of APLRs in use today utilise an airtight, vapour permeable, film layer to achieve their performance, Proctor Airs’ SMS (Spunbond Meltblown Spunbond) structure allows high levels of airflow in addition to the transport of moisture vapour, making the formation of condensation virtually impossible.

Independent studies of the effect of air permeability have confirmed that lofts using air permeable underlays have more consistent air-flow through the roof than those found in traditionally ventilated lofts, according to BS5250, so whatever side of the vents/no vents debate you sit on, Proctor Air has it covered.

Its heavyweight 170gsm three-layer structure also containing a hydrophobic in every layer, gives a Class W1 rating under the latest EN13859-1 specifications.

Key Features

Vapour Permeable

Proctor Air has an Sd-value of 0.015m and a vapour resistance of 0.075 MNs/g, making Proctor Air one of the highest performing vapour permeable membranes on the market.

Full Air Permeable

Air permeable membranes allow air movement through the roof, as well as allowing moisture to escape by diffusion. This means that condensation is far less likely to form on the membrane itself, and also allows the membrane to deal with much higher moisture levels within the building, for example during the drying out period.

Highly Water Resistant

Proctor Air is rated W1 under EN13859-1, and has a hydrophobic additive in all 3 layers. The membrane can be left exposed to provide temporary weather protection to the building envelope for up to three months (see FAQs, page14-15).Proctor Air has a Hydrostatic Head of water of over 1m as recommended by NFRC Technical Bulletin 6. It is good practice not to leave the underlay exposed longer than necessary.

Wind Uplift Resistance Complies with BS5534

Based on fully independent 3rd party testing, Proctor Air can be utilised across the UK.This, in addition to no requirement for high level ventilation or the use of a vapour control layer, ensures Proctor Air remains the simplest and most cost effective method of achieving regulation compliance.

More Uniform Airflow than Vents

The air permeability of Proctor Air means a non-ventilated roof fitted with Proctor Air allows a more consistent air flow through the roof than a roof ventilated as per BS5250, without expensive and time-consuming ventilation hardware fitted to the roof.

BBA Certificate 24/7147

Proctor Air is fully BBA certified for use in non-ventilated warm or cold roof applications.

Solar / PV Panels

A unique feature of Proctor Air’s BBA certificate is the clarification that it can be used on roofs featuring solar PV. Consideration may be required with regards to specific installation criteria for the PV assembly being used. In line PV assemblies can be used, without any additional ventilation or counter battens, when installed with a minimum of two tile zones around the perimeter of the PV Assembly. Alternatively, at the ridge, the two tile zone can be replaced with a dry ridge system above the PV Panel. PV assemblies mounted above the slates or tiles do not require any additional consideration.

No VCL Required

Installing Proctor Air will mean that a vapour control layer is not required for non-ventilated cold pitched roof constructions.

15 Year Warranty

Proctor Air’s 15-year warranty provides peace of mind on any project.

Energy Efficiency

Energy Loss by ventilation in conventionally ventilated cold roofs will be significantly reduced by the non-vented system.