Hi-line Industries Ltd have considerable experience in the supply of alternative filter elements which are ‘copy exact’ replacements for original equipment fitments.

Filter elements are consumable wear parts that are essential in providing the maximum protection to downstream equipment and production processes.

However these products can also fall in the ‘fit and forget’ category, with damage caused to capital equipment or production output if they become blocked with particulate or otherwise operate at high differential pressures.

With over 147,000 different filter elements to cross reference from utilising their own electronic software, the supply of appropriate alternative filter elements from Hi-line has never been simpler. Their aim is to provide a ‘one-stop’ filtration service for industry, whereby they can undertake to supply both original filtration equipment as well as optional, highly-economic alternative cartridges wherever applicable. Their range of filter elements fit into existing filter housings without modification, and will be of equal performance as the original branded products, or in many cases will outperform them.

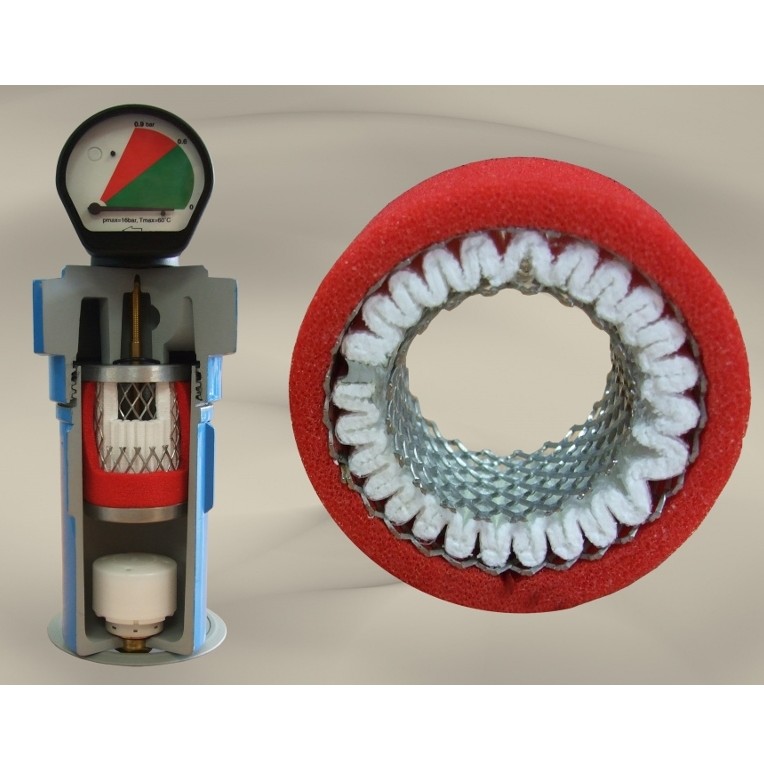

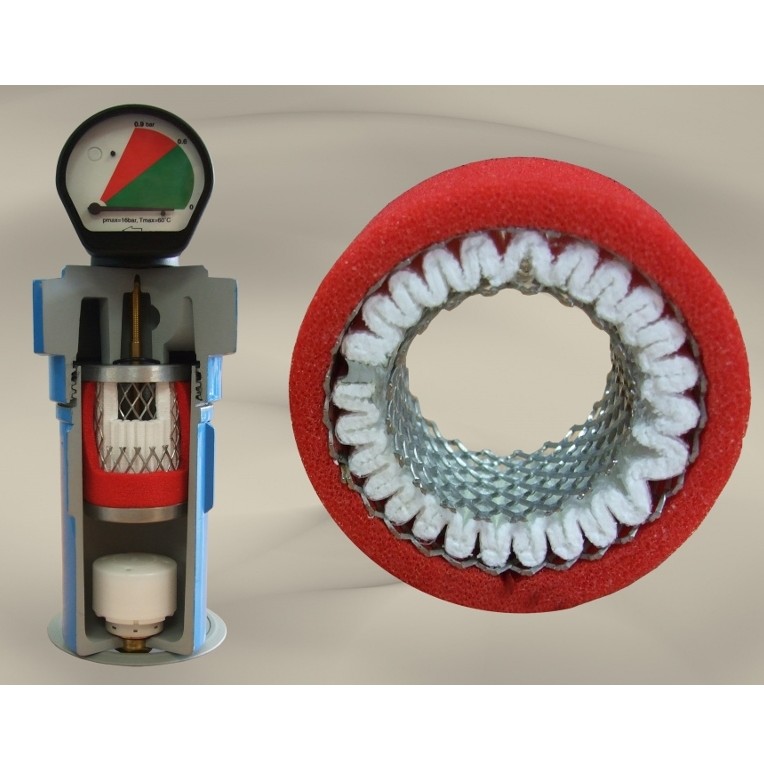

The Hi-line elements are all manufactured to ISO 8573-1:2010 with a pleated media construction which provides more than four times the filtration area than conventional wrapped or rolled media filters. In addition they ensure less oil carry-over, with longer service life and lower differential pressure. The larger cross section filtration areas require a much lower energy source during operation, and the Hi-line alternative filter elements can also be less expensive than original part replacements.

Replacement filter elements can be supplied for a wide range of fluid applications including compressed air (coalescing, air drying and vacuum), hydraulics, water, grease, gas (using microfibre technology) and chemicals (absolute and semi-absolute).

Special purpose filters can be supplied for compressors (filters, separators and intake) autoclave (venting), panel filters (reloadable filter frames), bag filters and filter baskets. The varying specialised filtration functions cover self-cleaning and backflushing, stainless steel filters and strainers as well as Duplex and Simplex strainers.

Specialised media available includes activated carbon and HEPA filters, together with spun bond polypropylene and wound cartridges. Process filtration can be supplied for breweries, dairies, pharmaceutical and general manufacturing, together with sterile filters for medical, laboratory and dental applications.