As widely reported, the recession caused a vast fall in the demand for bricks, resulting in many kilns ceasing to manufacture and bricklayers having to find alternative employment. As the industry emerged from the downturn, in 2014, it became clear that housebuilders were challenged by two major factors - a shortage of materials and traditional labour skills.

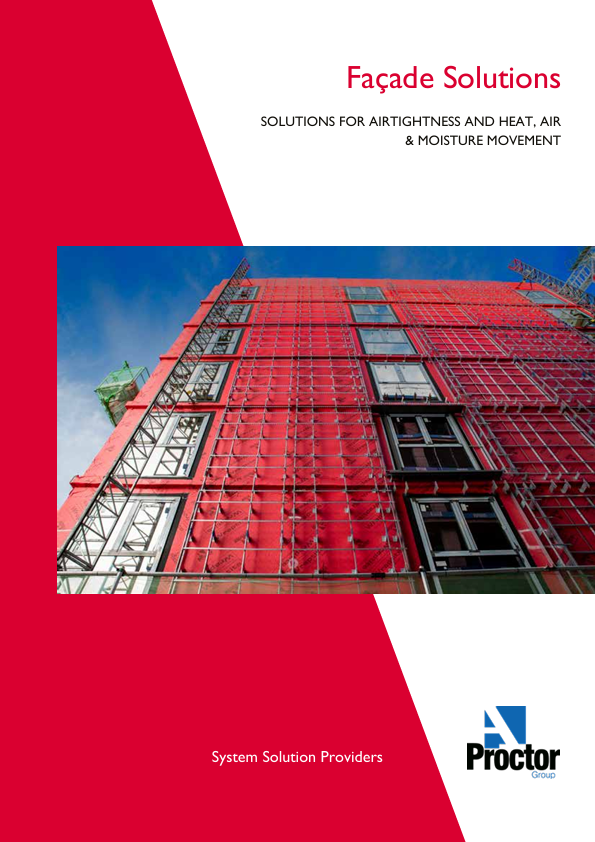

Although many businesses grappled to find the best way forward, Alumasc Facade Systems turned this situation into an opportunity by developing a new and innovative facade technology designed specifically for the offsite structural timber sector – the Alumasc Ventilated System (AVS).

The initial product development remit was to design a ventilated system that would replicate traditional building aesthetics, whilst providing a lightweight solution that could be fixed directly to structural timber systems. Alumasc’s main goal was to ensure the system was engineered to deliver structural stability across all applications whilst providing adaptability to all forms of structural timber construction.

This innovative, engineered system provides the solution to overcome the fundamental issues of the brick shortages. AVS, as an offsite manufactured system, improves efficiency and speed of construction, addresses skills shortages and enhances the quality of finish, whilst delivering the final aesthetics to meet the exacting requirements of architects, designers and housebuilders.

The product offers specifiers a ventilated cladding solution for timber frame construction, together with volumetric modular and structurally insulated panel systems (SIPS). It protects the fabric of the building whilst providing a wide choice of aesthetic options. The system accommodates a range of cavity depths - the free-flowing system ensures that the substrate remains continuously ventilated and prevents any moisture tracking back to the primary structure, removing condensation – providing a protective facade.

Offering an alternative method of construction, AVS can replicate any brick in the market via patented, lightweight acrylic brick slips. The system is not just limited to using acrylic brick slips as the final facade finish - it is also approved for use with textures, through-coloured silicone renders, along with an extensive range of dashing renders.

AVS is erected via Alumasc’s network of registered installers to ensure correct application onsite. The AVS installer training programme is independantly assessed and approved by the BBA. AVS comes with a 10 year warranty offer for all projects installed by an Alumasc registered contractor.

Technical Approval

The AVS system has been rigorously tested, resulting in compliance with all UK Building Regulations and became British Board of Agrément approved (Cert No: 15/5211) in May 2015. It is the only ventilated system in the UK to be BBA certified with an external acrylic brick slip finish and offers an industry-leading A2 rating, providing the building with improved fire performance when compared to other cladding solutions.

During the development of the system, Alumasc worked very closely with a number of companies and bodies to ensure AVS would meet the demands of the offsite and onsite construction industry, whilst providing optimum performance and longevity. These organisations include CCG, Exova Fire Research, Warrington (fire testing); Lucideon (UKAS accredited testing body); Pell Frishmann (Consultant Engineers) and the British Board of Agrément.

AVS is the solution to overcome current construction industry skills issues and is well-positioned to be part of the building technology of the future.

Advanced Facade Solution for Structural Timber Construction

Taking its name from the historic use of the adjacent canal – Alumasc supplied their Alumasc Ventilated System to the Timber Basin in Panmure Street. This project will provide 108 new homes for Queens Cross Housing Association. The mixed use residential scheme incorporates social housing and shared equity homes for first-time buyers. Panmure Street includes numerous building types from two and three bedroom town houses to five and even eight storey apartment blocks.

The Panmure Street development in Glasgow demonstrates the benefits and versatility of using the Alumasc Ventilated System (AVS). On this scheme a closed panel, fully offsite manufactured solution was delivered, with only a small element of external onsite fabric work required.

CCG - who have recently invested over £12m in a state-of-the-art factory, were the main contractor and offsite manufacturer on the scheme, installing AVS with a lightweight acrylic brick slip finish.

AVS offers an alternative approach to traditional build, particularly for new build timber framed housing. It provides an engineered, stylish facade solution, with the option of utilising modern offsite construction techniques. Due to the system’s free flowing cavity, it remains both continuously ventilated and drained whilst maintaining detailing true to traditional build expectations. This ensures the timber substrate sustains its ventilation requirements, removing condensation and preventing moisture tracking back to the building fabric, providing a protected structure. AVS is approved for use with acrylic brick slips, silicone render and dashing render.

Paul Muldoon, Contracts Manager for CCG said: “The Panmure project is one of the largest projects using closed panel technology to be manufactured offsite in our new factory. Due to the design of the Alumasc Ventilated System we were able to apply 75% of the brick slips offsite therefore the usual challenges such as transport logistics, site access problems and weather did not impact on the project.”

The key driver for the specification of AVS was its ability to replicate traditional construction design whilst being adaptable for the closed panel production line.

AVS is quick and easy to install and can be produced in factory controlled conditions, enhancing quality and minimising onsite waste whilst offering a rapid and reliable build programme, not effected by adverse weather conditions.

Alastair Wylie, Group Chairman and Chief Executive of CCG commented: “The Alumasc Ventilated System for timber frame provides a significant advancement in the concept of Modern Methods of Construction and furthermore relieves the pressure upon skill and material shortages.”

For more information visit: http://avs.alumascfacades.co.uk/

To book a CPD seminar please email: facades@alumasc-exteriors.co.uk