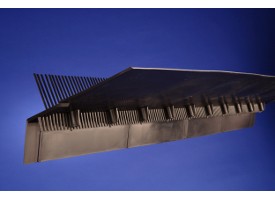

To mark the joint 100-year anniversaries of the first patent for PVC manufacture and the first flight of the World War 1 Sopwith Camel biplane, PVC Roofline and Rainwater specialists Swish Building Products had this beautiful, large-scale static model built using their cellular PVC facia boards.

The Sopwith Camel first flew on 22nd December 1916 and went on to be the most successful allied fighter with 1294 victories to its name. Of the 5490 built, only eight are thought to remain.

In recognition of the event, Swish thought it would be a great idea to build this 1/8th scale model, making the wings, fuselage and control surfaces from their off-the-shelf cellular PVC facia and soffit boards.

The model was painstakingly crafted over several weeks and faithfully reflects the detail, balance and elegance of the original machine.

Also around 100 years ago, industrial chemist, Friedrich Heinrich August Klatte became the first inventor to receive a patent for PVC with a polymerization method for vinyl chloride using sunlight.

To further mark these significant Centenary milestones and in response to customer demand, Swish is also launching new ranges of their fascia and soffit boards in cream and white foil finishes.

These will join Swish’s wider and fully integrated range of robust, cellular PVC profiles.

Like the existing products, they are weather resistant and virtually maintenance free.

Modern Swish PVC rainwater systems are ideal for those who want to specify quality products that have a significantly reduced carbon footprint. These products marry a recycled core with a virgin skin and save 70% of the CO2 that would be produced by manufacturing with virgin material only.

Swish cellular PVC also represents an environmentally responsible use of plastics. It is manufactured in an efficient and environmentally responsible manner. Swish takes its environmental responsibilities very seriously and holds ISO 14001 Environmental Management Certification under which a continuous programme of targets, actions and monitoring ensures that the company uses resources efficiently and that energy and water consumption and waste of any kind is kept to a minimum.

Few other construction materials are as versatile or able to meet such demanding specifications.